What B2B Buyers Should Know About Sanding Discs

In the automotive refinishing industry, sanding discs might seem like small components—but seasoned professionals know that choosing the right one can make a significant difference in efficiency, finish quality, and even long-term cost control.

If you’re a B2B buyer sourcing abrasives for a repair shop, distribution center, or industrial finishing line, here’s what you should keep in mind before placing your next order.

1. Not All Grits Are Created Equal

It’s tempting to judge a sanding disc simply by its grit number, but that’s only part of the story. Two discs with the same grit rating may perform very differently depending on the grain material and bonding technique. For automotive applications, aluminum oxide is common, but premium options like ceramic or zirconia alumina can offer longer life and better heat resistance—especially when dealing with tough coatings or metal panels.

Tip: Match your grit type to your workflow. Use coarser grits for filler leveling and finer grits for final prep before painting.

➡️ Explore our full range of sanding discs

2. Backing Material Matters

Backing isn’t just the thing holding the abrasive—it affects flexibility, durability, and performance consistency. Paper backings are more economical and great for dry sanding, while film and cloth backings offer tear resistance and better surface conformity. For orbital sanders, film-backed discs tend to provide more even finishes, especially when working on curved body panels.

OEMs and high-volume shops often favor film discs because they reduce rework caused by swirl marks.

3. Hook & Loop or PSA?

Hook and loop (Velcro-style) discs are quick to change, making them ideal for shops that frequently switch between grit sizes. Pressure-sensitive adhesive (PSA) discs, on the other hand, provide more contact stability and are often used in continuous production settings.

Tip: Choose hook & loop for flexibility and time savings; PSA for consistent pressure on large flat panels.

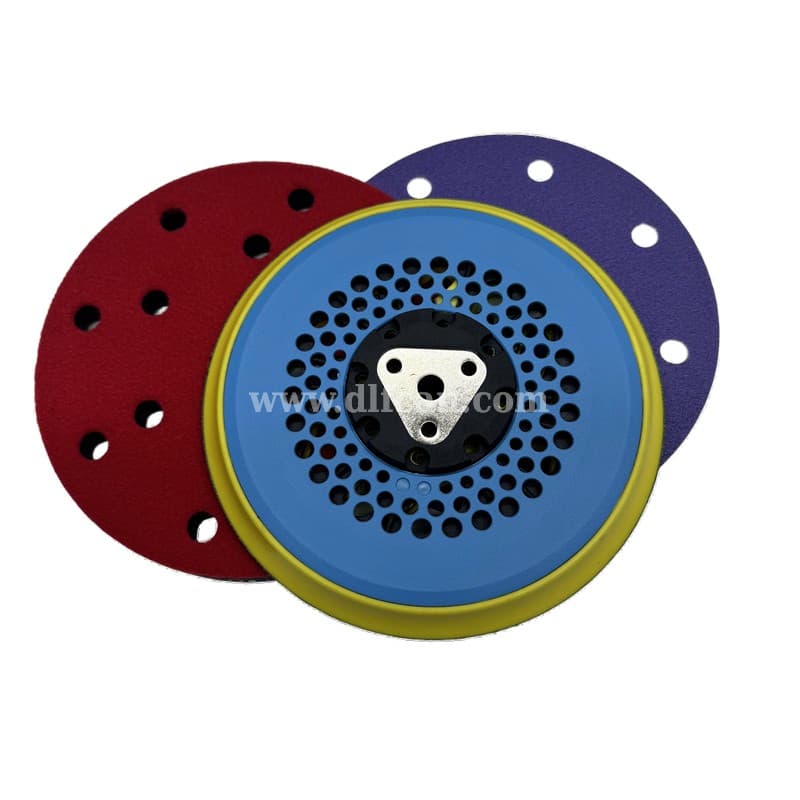

4. Don’t Overlook Dust Extraction Compatibility

Modern body shops prioritize clean air and efficient workflows. Using sanding discs with vacuum hole patterns—matched to your sander’s pad—can significantly reduce airborne dust, improve abrasive performance, and extend disc life.

When sourcing, make sure the disc pattern (e.g., 6-hole, 8-hole, multi-hole) aligns with your equipment. A mismatch not only reduces suction efficiency but can also void tool warranties in some cases.

5. Bulk Buying Doesn’t Mean Compromising Quality

For B2B buyers, price per disc is important—but don’t let it override performance. A low-cost disc that wears out in half the time will actually cost you more in labor, changeovers, and rework. Always consider price per completed job, not just price per unit.

At DLF Can, we work closely with workshops and distributors to balance quality and cost—offering volume discounts without sacrificing reliability.

➡️ View our sanding equipment catalog

6. OEM Customization Can Set Your Brand Apart

If you’re a distributor or regional supplier, offering private-label abrasives with your branding can increase customer loyalty and repeat sales. Many manufacturers—including us—offer OEM customization options on disc size, grit range, packaging, and branding.

➡️ Learn more about our OEM customization services

Final Thoughts

Sanding discs may be small, but they’re critical to your finishing workflow. As a B2B buyer, taking the time to understand materials, compatibility, and performance can yield long-term returns—both in operational efficiency and customer satisfaction.

If you’re looking for sanding discs built for professional use—with options for bulk purchase, OEM branding, and fast global delivery—DLF Can is ready to assist. Let’s work together to supply your workshop or network with the right abrasives, every time.